When it comes to troubleshooting 3D printing, moisture can be a significant issue. When filament absorbs even just a small amount of humidity, you may be left with an end-product full of bubbles, stringing, or poor layer adhesion. Moisture can also result in brittle prints and clog a printer’s nozzle.

For this reason, you must have a filament dryer on standby. In 2025, smart filament dryers offer more than just heat. They come automated and programmed to provide real-time monitoring and control, allowing you to combat moisture every time you print.

Continue reading to learn about the essential features your filament dryer should have to improve your 3D prints.

Table of Contents

Toggle- Temperature Control and Smart Presets

- Even Thermal Distribution With Air Circulation

- Real-Time Monitoring and Automatic Dry Cycles

- Feed-Through and Inline Support

- Capacity and Modular Storage Options

- Safety and Environmental Controls

- Remote Control

- Eco-Friendly Options

- Best Practices When Using a Smart Filament Dryer

- Smart Filament Dryer Features Are a Must-Have in 2025

Temperature Control and Smart Presets

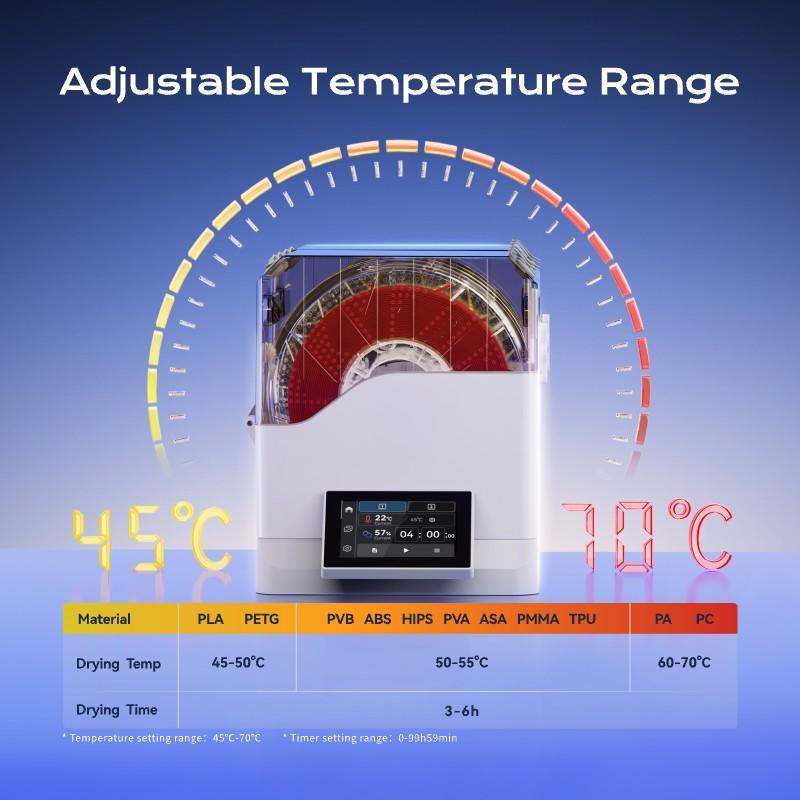

A must-have for any filament dryer is the option to set specific drying temperatures. For instance, you must be able to:

- Dry PLA at 104-122°F for 4 to 6 hours.

- Dry PETG at 149°F for 4 to 6 hours

- Dry Nylon or Polycarbonate at 176 °F for 6 to 12 hours

- Dry TPU or flexible material at 104-113°F for 4 to 6 hours

If your filament dryer cannot provide precise heating control, you may under-dry sensitive material, or softer filaments may overheat, which will deform the result.

Smart features to look for include one-touch presets for different materials, customizable timers, and manual overrides.

When you apply consistent heat, you can dry your filament without stressing it or altering its dimensions. This results in better first-layer adhesion and smoother final surfaces.

Even Thermal Distribution With Air Circulation

If your filament dryer does not have sufficient airflow, it may create hot spots, resulting in uneven drying. When the heat is not distributed evenly, filaments in low-flow zones will stay damp.

What you need is 360° PTC heating to ensure the entire filament is consistently warm. Internal fans should circulate the heated air. Ideally, you want a dryer with a triple-fan system or ring-style ducting. This is the most effective way to maintain a temperature within a range of ±5.4 °F.

Real-Time Monitoring and Automatic Dry Cycles

Filament dryers that continue to recirculate air may reach a plateau where no more moisture is removed. Humidity must consistently be expelled or absorbed to allow for true drying.

Therefore, a filament dryer should:

- Have an integrated hygrometer that displays humidity levels.

- Have auto-humidity modes that trigger drying cycles whenever there is an increase in humidity levels.

- Push humidity below 10% RH.

With these features, you get ongoing feedback on how dry your filament is. Also, you can set your dryer to maintain the ideal drying temperature reactively.

Feed-Through and Inline Support

Even if a filament is completely dry, it can still reabsorb moisture during printing. This typically happens when the filament is exposed to ambient air.

Consider the following features to prevent this from happening:

- Feed-through connectors that allow for direct printing while drying.

- A wall-mounted model that can clean and dry filament before guiding it into the printer.

When you print and dry filament simultaneously, it can prevent rehydration. As the filament remains dry, it ensures good extrusion and prevents artifacts during the printing process.

Capacity and Modular Storage Options

Your 3D printing needs are not the same as those of another person. You may need a filament drying that caters to single spools or multi-material projects.

The smart features to look for include:

- A compact dryer that can handle one to two spools. If you work with multiple materials simultaneously, consider a larger model that supports four or more spools.

- You can also look into stackable or modular systems that make it easier to scale your 3D print setup.

- Some designs include desiccant compartments or interchangeable drying modules.

Safety and Environmental Controls

Drying filament should be a regulated process. If the temperatures are not managed, it will warp the filament. In worst-case scenarios, overheating may even result in a fire.

These issues can be prevented through the following features:

- PTC thermistors and overheat cutoff circuits

- Tilt sensors that shut off the heating process if the unit falls

- Fan and temperature failure detection in real time

You need these automated fail-safes if you want to run a long-acting cycle or print overnight.

Remote Control

Filament dryers also offer remote control options, such as Wi-Fi or Bluetooth. You can use this connectivity to control the dryer’s settings via an app. Plus, you can set alerts for heating status, humidity trends, and job completion.

Some high-end filament dryers also have the option to schedule and monitor filament weight and humidity inside the chamber.

When you have remote oversight of the printing process, you’ll experience fewer interruptions. Remote oversight also enables you to improve precision, particularly for multi-unit setups.

Eco-Friendly Options

Filament dryers typically require several hours of operation to maintain a low humidity level. Over time, this can impact your operating costs and have a detrimental effect on the environment.

If you want to mitigate this impact, look for a dryer with:

- Low-power PTC heating elements. Many modern dryers feature positive temperature coefficient (PTC) ceramics that self-regulate heat to minimize power consumption.

- You can also opt for a dryer with a standby mode option. When the dryer enters standby mode, it consumes only around 100W during active drying and even less afterward.

- Cycle control. If your dryer has user-set timers and humidity sensors, you can avoid unnecessary heating. Your dryer will only cycle when needed to maintain optimal conditions, thereby reducing the energy draw.

Best Practices When Using a Smart Filament Dryer

To make the most of your filament dryer when 3D printing, consider the following best practices.

- Always select the right filament profile or preset before starting a 3D project.

- Pre-dry all high-humidity materials for 12 to 24 hours above 158°F.

- Monitor the humidity levels during drying until they reach ≤10% RH.

- Use feed-through features (if available) for uninterrupted printing.

- Transfer spools to dry storage after they have been dried, or set a smart unit to maintain a dry environment.

- Regularly clean the dryer chamber and inspect the seals for damage.

Smart Filament Dryer Features Are a Must-Have in 2025

Smart features continue to enhance filament dryers in 2025 and, by default, improve 3D printing. If you choose to work with a filament dryer that incorporates smart features, you will quickly notice a vast difference in print quality and efficiency every time.