In a world where ideas can materialize before your eyes, the role of a 3D printing engineer is nothing short of magical. Imagine being the wizard who transforms digital dreams into tangible reality, all while dodging the occasional filament disaster. It’s not just about pressing a button; it’s about crafting intricate designs that can revolutionize industries—from healthcare to aerospace.

Table of Contents

Toggle3D Printing Engineer

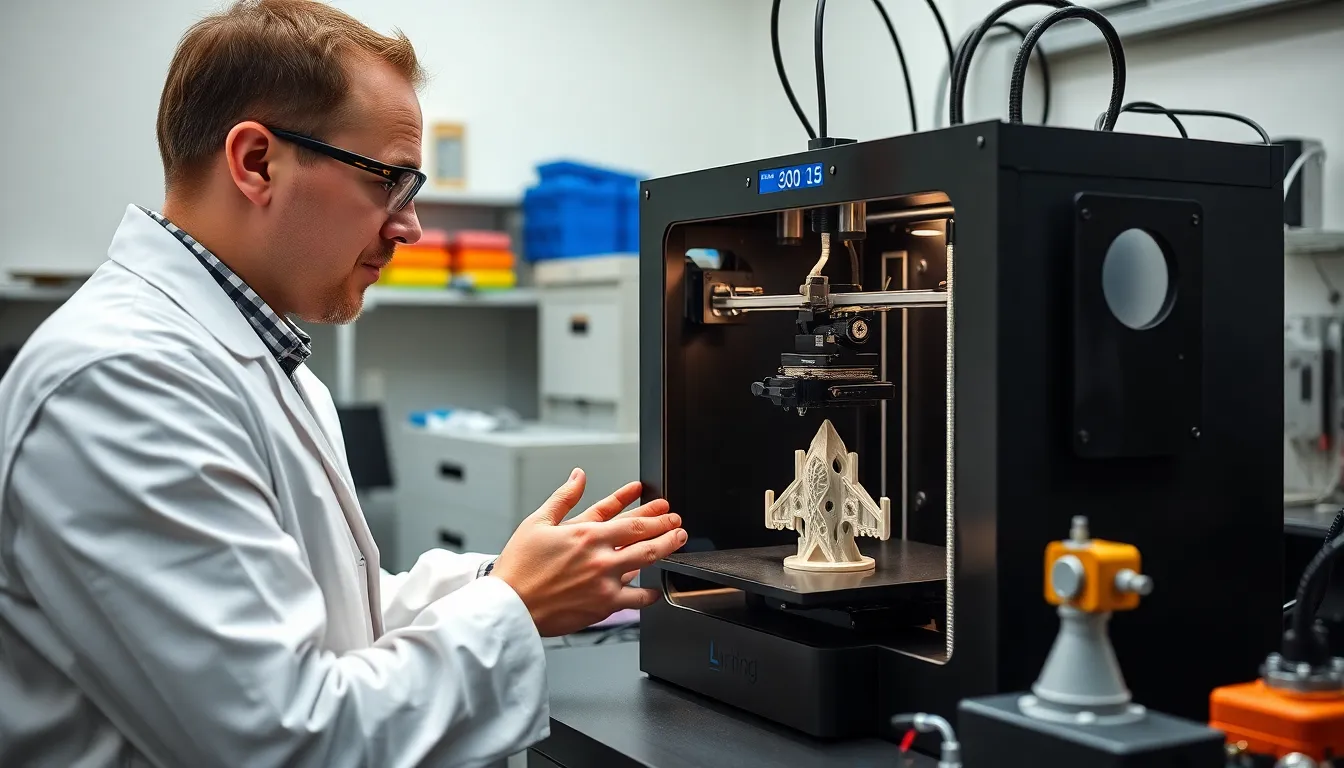

A 3D printing engineer transforms digital designs into tangible products. This role encompasses many responsibilities that combine creativity and technical expertise.

Overview of Responsibilities

3D printing engineers design 3D models using computer-aided design (CAD) software. They select appropriate materials for projects, ensuring the final product meets specifications. Engineers troubleshoot issues during the printing process, addressing problems like filament jams or print failures. Additionally, they work closely with clients to comprehend their requirements, modifying designs as needed. Maintaining and calibrating 3D printers guarantees high-quality output. Many engineers also document processes and suggest improvements for more efficient production.

Necessary Skills and Qualifications

A solid background in engineering or a related field forms the foundation for a 3D printing engineer. Proficiency in CAD software is essential for creating complex designs. Familiarity with various 3D printing technologies, like FDM, SLA, and SLS, enhances an engineer’s capabilities. Strong problem-solving skills facilitate quick resolutions to production challenges. Effective communication fosters collaboration with team members and clients. Finally, attention to detail ensures precision in models and adheres to industry standards.

Industries Utilizing 3D Printing Engineers

3D printing engineers play a crucial role across multiple industries, revolutionizing manufacturing processes and enhancing product development. They contribute to innovation in aerospace, automotive, healthcare, and dentistry, among others.

Aerospace and Automotive

Aerospace and automotive sectors heavily rely on 3D printing engineers for rapid prototyping and producing complex parts. Engineers design lightweight components that improve fuel efficiency in aircraft and vehicles. They create intricate geometries that traditional manufacturing methods struggle to achieve. Additionally, rapid production significantly reduces lead times, allowing companies to respond quickly to market demands. For example, industries use 3D printing to manufacture customized parts for aircraft, which improves performance and safety.

Healthcare and Dentistry

Healthcare and dentistry benefit tremendously from the expertise of 3D printing engineers. Customized implants and prosthetics tailored to individual patients emerge from their innovative designs. This personalization promotes enhanced comfort and functionality for patients. Engineers also produce dental models and surgical guides with precision, streamlining procedures for healthcare professionals. The ability to iterate designs quickly supports advancements in treatment options, pushing the boundaries of medical possibilities. For instance, 3D printing enables the creation of bio-compatible materials that help enhance patient care and expedite recovery.

The Future of 3D Printing Engineering

The future of 3D printing engineering showcases significant advancements and opportunities. Engineers increasingly leverage emerging technologies for enhanced capabilities.

Emerging Technologies

Advancements in materials science introduce innovative options like bio-based filaments and metal composites. These materials enhance performance characteristics and expand application potential. Integration of artificial intelligence optimizes design processes, enabling rapid adjustments and improved accuracy. Process automation with robotics streamlines manufacturing workflows, reducing production times. Additionally, tighter collaboration with industries fosters the development of specialized printing techniques tailored to unique needs. Reality captured through 3D scanning technologies facilitates reverse engineering and customization. Engineers now explore possibilities in areas like 4D printing, where printed objects can change shape over time. Each of these trends contributes to a more efficient and versatile 3D printing ecosystem.

Career Opportunities

Career pathways in 3D printing engineering expand as industries recognize its value. Positions such as additive manufacturing specialists and technical sales engineers grow increasingly popular. Organizations seek engineers skilled in various software programs to design and simulate prints effectively. Professionals can explore roles focused on research and development, contributing to innovative projects. Additionally, opportunities exist in project management, overseeing the entire lifecycle of 3D printing operations. Freelance or consulting roles appeal to those who prefer flexible work environments. Demand for experts proficient in material science and process optimization continues to rise. Each opportunity underscores the versatility of a 3D printing engineer’s skill set.

Challenges Faced by 3D Printing Engineers

3D printing engineers encounter various challenges that impact their work quality and efficiency. Understanding these challenges is essential for improving processes and outcomes.

Technical Challenges

Technical challenges arise during the design and fabrication processes. Filament compatibility issues can lead to failed prints or compromised quality. Engineers often face difficulties with print resolution, impacting the final dimensions and surface finish of products. Additionally, material selection can be complex, as not all materials perform equally across different printing technologies. Calibration problems may also affect printer performance, resulting in wasted time and resources. Engineers must troubleshoot and optimize parameters continuously to maintain high standards.

Market and Industry Challenges

Market challenges impact the growth of 3D printing engineering. High equipment costs can deter companies from adopting new technologies. Furthermore, the fast-paced nature of the industry creates pressure to stay current with emerging trends and innovations. Engineers often contend with intellectual property concerns, as designs may be vulnerable to unauthorized reproductions. Collaboration across industries poses its own challenges as each field has unique requirements and standards. Navigating these complexities requires engineers to be adaptable and proactive in their approach.

Conclusion

The role of a 3D printing engineer is pivotal in today’s rapidly evolving technological landscape. Their unique blend of creativity and technical expertise enables them to drive innovation across various sectors. As industries increasingly adopt 3D printing, the demand for skilled engineers continues to grow.

Facing challenges head-on, these professionals adapt to new materials and technologies while ensuring quality and efficiency. With the potential for advancements like 4D printing and AI integration, the future looks bright for 3D printing engineers. Their contributions not only enhance product development but also reshape how industries approach manufacturing and design.