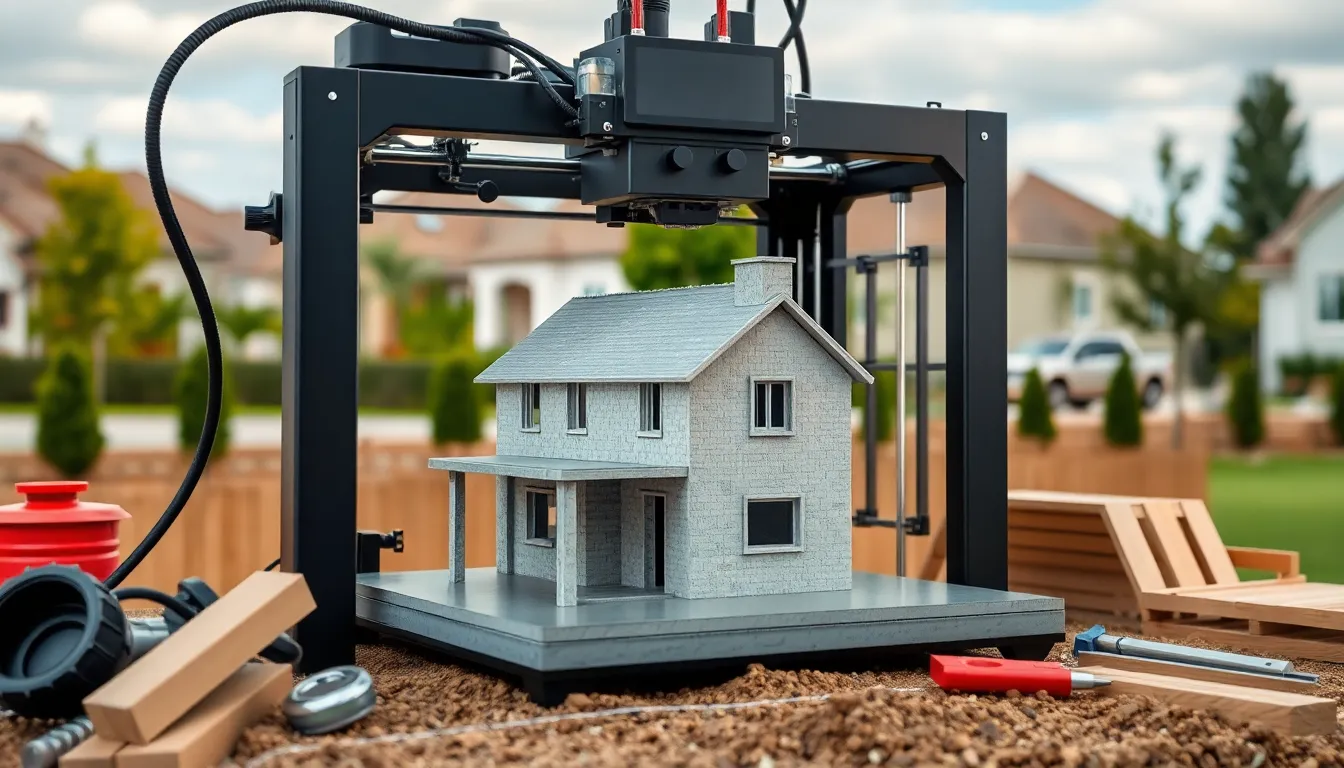

Imagine living in a house that popped up faster than you can say “pass the remote.” Welcome to the world of 3D printing, where dreams of homeownership are being transformed into reality—literally! This revolutionary technology is reshaping the way we build, making it possible to print entire houses in mere days.

Gone are the days of waiting months for construction crews to finish your dream home. With 3D printing, you can skip the endless meetings and surprise costs. Instead, you get a stylish, affordable home that’s customized to your liking. So grab your hard hat and get ready to explore how this futuristic approach is not just a trend, but a game-changer in real estate. Who knew building a house could be as easy as hitting “print?

Table of Contents

Toggle3D Printing A House

3D printing technology revolutionizes home construction by enabling the rapid creation of entire houses. This method utilizes large-scale printers, which deposit materials layer by layer, allowing for efficient and precise building processes. Construction timelines dramatically decrease, with some homes completed in less than a week.

Sustainability benefits are significant. Many 3D printed houses use eco-friendly materials, reducing waste compared to traditional construction. Also, the potential for lower labor costs makes this approach financially attractive.

Customization options abound. Homebuyers can design unique floor plans tailored to their preferences, enhancing personalization. Advanced software programs facilitate this design process, ensuring easy adjustments to meet client needs.

3D printing also addresses housing shortages. By quickly producing affordable homes, it serves communities in need, increasing access to homeownership. Several projects already demonstrate success in various regions, showcasing scalability and adaptability.

Innovations continue to emerge in this field. Various companies explore different materials, including concrete and biodegradable substances, enhancing the capabilities of 3D printed structures. Engineers and architects consistently find new ways to improve structural integrity and aesthetics.

The future appears bright for 3D printing in construction. As technology advances and becomes more widely adopted, it holds the promise of transforming the housing market, making homes more accessible and sustainable.

Benefits of 3D Printing a House

3D printing a house offers significant advantages, transforming the construction industry.

Cost Efficiency

Cost efficiency ranks high among the benefits of 3D printing homes. Traditional construction often carries substantial expenses for materials and labor, driving up prices. In contrast, 3D printing uses less material and generates minimal waste, which reduces overall costs. Estimates from various projects show that this method can lower building expenses by up to 30%. Additionally, fewer workers are needed on-site, further cutting labor costs. Homebuyers can enjoy affordable housing options, especially in areas facing economic challenges. Affordable materials combined with innovative technology create a budget-friendly housing solution.

Time Savings

Time savings represents another key benefit of 3D printing homes. Conventional construction can take months to finish a single house. 3D printing, however, allows for entire homes to be constructed in as little as 24 hours. This rapid turnaround helps address urgent housing shortages by swiftly delivering homes to communities in need. Quick assembly also results in less exposure to weather-related delays, ensuring timely project completion. Increased efficiency not only benefits builders but also supports homeowners looking for faster move-in dates. Overall, the speed of 3D printing fundamentally reshapes timelines in home construction.

The 3D Printing Process

The 3D printing process in home construction involves precise methods for creating structures efficiently. This innovative approach starts with meticulous preparation and planning to ensure a successful build.

Preparation and Planning

Preparation plays a critical role in 3D printing a house. It begins with the design phase, utilizing advanced software to create tailored blueprints. Accurate measurements and specifications set the foundation for the project. Engineers and architects collaborate to address potential challenges and optimize the layout. Once finalized, project teams assess local regulations and zoning laws, ensuring compliance throughout the process. Timelines and budgets are established to facilitate smooth execution. Effective communication among stakeholders helps streamline operations.

Materials Used

The materials used in 3D printing significantly influence the construction outcome. Concrete and various composites are common choices, known for durability and flexibility. These materials enable the creation of intricate designs and structures. Many companies also explore sustainable options, such as recycled materials, promoting environmental responsibility. Innovative mixtures, including thermoplastics, enhance strength and thermal performance. Moreover, the adaptability of materials allows for customization based on geographical and climatic needs. This versatility contributes to the overall efficiency and effectiveness of the construction process.

Case Studies of 3D Printed Houses

Numerous case studies highlight the viability and impact of 3D printed houses globally. These projects exemplify the capabilities and advantages of this emerging technology.

Notable Projects Around the World

In Texas, Icon completed a neighborhood of 3D printed homes called Community First! Village. This initiative focuses on providing affordable housing for the homeless and demonstrates how rapid construction can create sustainable communities. Similarly, in the Netherlands, Project Milestone features five 3D printed homes that will serve as a prototype for future housing. Finally, in Mexico, the company New Story partnered with ICON to build an entire neighborhood in under 24 hours, showcasing the potential to address housing shortages efficiently.

Lessons Learned

Innovators have gained valuable insights from these projects. Effective collaboration among architects, engineers, and construction teams enhances project success. Adapting to local building codes and regulations proves essential for smooth execution. Learning from initial attempts helps companies refine their printing techniques and material choices. Involvement of the community fosters greater acceptance and helps tailor designs to residents’ needs. These experiences underscore the importance of continuous improvement and the potential for long-term impact in the housing market.

Future of 3D Printing in Construction

Advancements in 3D printing technology shape the future of construction. Predictive models suggest that this approach could dominate the market, especially in urban areas facing housing crises. Innovative materials, including sustainable composites and recycled resources, contribute to an environmentally responsible construction process. Customization enhances user experience, allowing homebuyers to create homes that fit their lifestyle.

Collaboration among industry stakeholders fosters efficiency and innovation. Engineers and architects work together, enhancing systems to adapt to local building regulations. As demonstrated by projects like Community First! Village in Texas, 3D printing offers scalable solutions for affordable housing. Successful integration of local community feedback ensures designs meet residents’ needs.

Production timelines shrink thanks to continuous improvements in printing techniques. Homes constructed in as little as 24 hours drastically reduce delays associated with traditional methods. Cost-reduction strategies, including material optimization, result in savings of up to 30%. Such advantages empower construction companies to provide affordable options in economically challenged areas.

Case studies from around the world illustrate the technology’s impact. Project Milestone in the Netherlands emphasizes a commitment to quality and durability, featuring five prototypes built to last. New Story’s collaboration with ICON in Mexico highlights the potential for entire neighborhoods built rapidly, demonstrating the urgency of addressing housing shortages.

Enhanced structural integrity emerges from the use of advanced materials in the printing process. Adjustments in design based on geographical and climatic factors ensure resilience in various environments. These developments point to a transformative future for the housing market, driven by 3D printing technologies that enhance accessibility and sustainability in construction.

Conclusion

3D printing is redefining home construction by offering a faster and more sustainable approach to building. With the ability to create customized homes in record time, this technology is addressing critical housing shortages while promoting affordability. As the industry embraces eco-friendly materials and innovative designs, the potential for widespread adoption grows stronger.

Future advancements will likely enhance the efficiency and adaptability of 3D printing, making it an essential tool in urban development. The collaborative efforts of architects, engineers, and communities will further drive the success of 3D printed homes. This transformative technology is set to play a crucial role in shaping a more accessible and sustainable housing market.