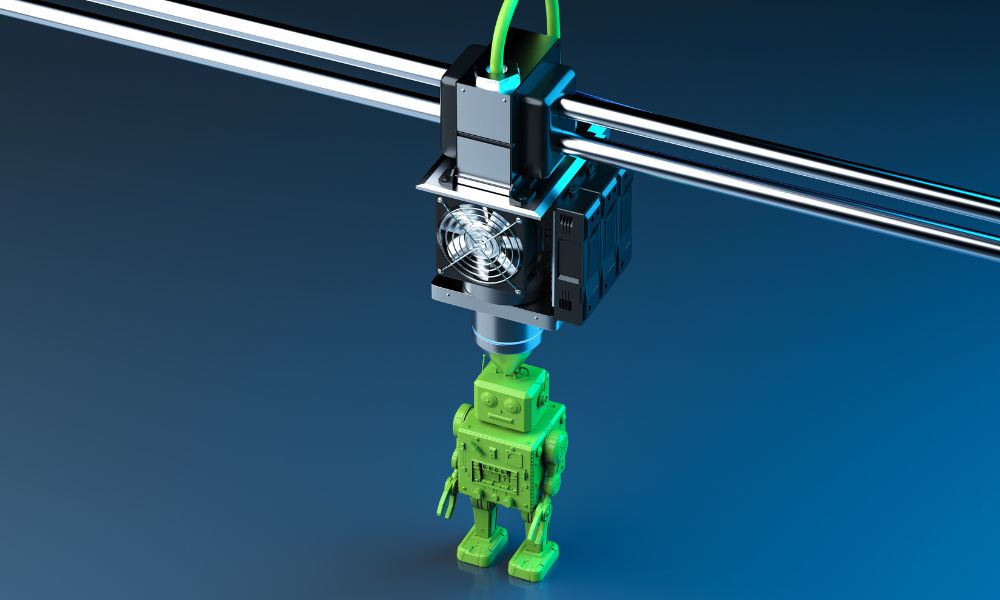

Production is a revolving door in the consumer goods industry. That door swings around every time a request for a product comes in, so it’s a never-ending cycle. Your company could come full circle in a doable time frame by using modern technology to speed up production. Let’s unravel that possibility by learning the benefits of using 3D printers for consumer goods.

Table of Contents

Toggle3D Printing Presents More Flexibility in Design

Design flexibility is the ultimate perk to 3D printing in the manufacturing industry. The number of tools grants creators endless possibilities to create structures they never could begin to imagine were possible. Countless industries have utilized this process throughout production cycles.

The beauty industry has taken 3D printing for a spin, creating better products for consumers that apply easier and are nice to look at. Beauty brands can design better mascara wands to absorb more product so customers don’t have to re-dip the wand several times.

3D Printing Speeds Up Production Cycles

Speeding up production is the dream for many manufacturers. However, traditional methods like CNC no longer work. New technology is necessary to bring normalcy back into the factory.

3D printing has made a splash in many ways for production companies. Many have improved production cycles, from the beginning stages to designing and adding finishing touches. The process has helped companies develop more accurate production processes. It allows the use of additional programs like a slicer application that translates 3D models into a language the printer understands.

The Printing Process Offers Better Customization

The customization of 3D printing is endless. The process nearly eliminates additional costs from third-party software or companies to design complex prototypes. 3D printing eliminates that by using only a person and a machine to create.

The 3D printer saves money in production by eliminating additional costs. Workers have more flexibility in design and time to perform quality control before sending an item to be finalized. Also, the 3D model designs are data, so if you have factories or small 3D printing shops elsewhere, you could easily send the data to that machine for faster printing.

It’s a More Sustainable Practice To Use

Sustainability is the way to go. 3D printing creates a cleaner working environment by allowing workers to reuse products and recycle most materials. The production process isn’t only faster, but it’s also much cleaner than other methods.

Now that you know the benefits of using 3D printers for consumer goods, start improving your production process with a printer. You will love these thorough methods that allow you to use other software to translate complex design data into a language your 3D printer understands. Maintain authority over your production process by adding a 3D printer to your cycle.