Thin film technology may not immediately come to mind when thinking about everyday life. Still, it plays a crucial role in our daily routines. Thin film technology involves the deposition of extremely thin layers of material onto a substrate, and its applications are diverse and often hidden from plain view. In this blog, we’ll explore eight surprising uses of thin film technology that impact our lives in ways we might not even realize.

Table of Contents

ToggleWhat are Thin Films?

Thin films are exceedingly thin layers of material that exhibit unique properties due to their nanoscale thickness. These films typically range from a few nanometers to several micrometers thick, making them lighter than a human hair. Thin films’ exceptional uniformity, flexibility, and substrate modification capabilities make them ideal for various applications.

Thin films are not limited to a single type of material; they can be composed of semiconductors, metals, or insulators, depending on the desired functionality. These materials are carefully selected to exploit their specific properties, further enhancing the versatility of thin film technology. For more detailed insights into thin film technology, you can also read the article by Korvus Technology.

How are Thin Films Made?

Several deposition methods are used to manufacture thin films, each with unique advantages and applications. Here are three common techniques:

Physical Vapor Deposition (PVD)

Physical Vapor Deposition, often termed PVD, involves transforming a solid material into a vapor phase, then condensation onto a substrate to form a thin film. Various techniques, such as evaporation, sputtering, or laser ablation, can achieve this method. PVD is favored for its ability to produce high-quality and uniform thin films, making it vital in industries like electronics and optics.

Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition, or CVD, relies on chemical reactions to deposit thin films onto a substrate. Precursor gases are delivered into a reaction chamber and undergo chemical reactions, creating a solid coating on the substrate surface. CVD is valued for its ability to coat complex three-dimensional shapes and its suitability for producing semiconductors and protective coatings.

Atomic Layer Deposition (ALD)

Atomic Layer Deposition, or ALD, is a precise and controlled technique that builds thin films one atomic layer at a time. ALD alternates between exposing the substrate to precursor gases, allowing one layer of atoms to react and form at a time. This method ensures unparalleled thickness control and conformity, making it indispensable in nanotechnology, semiconductor manufacturing, and microelectronics.

Now, let’s look at some of the remarkable applications of thin film technology that have a substantial impact on our daily lives, often in unexpected ways:

Anti-Reflective Coatings for Eyeglasses

Have you ever noticed how eyeglasses can have a reflected glare at times? Thin film coatings are used to reduce glare and improve eyesight clarity.

Anti-reflective coatings are added to eyeglass lenses, allowing more light to pass through, minimizing glare, and improving overall visual experience.

Energy-Efficient Windows

Energy-efficient windows are a vital component in today’s sustainable construction practices. Thin film technology creates low-emissivity (low-E) coatings on glass surfaces. These coatings help regulate indoor temperature by blocking unwanted heat transfer while allowing natural light to enter. As a result, the amount of energy used for heating and cooling is reduced.

Solar Panels

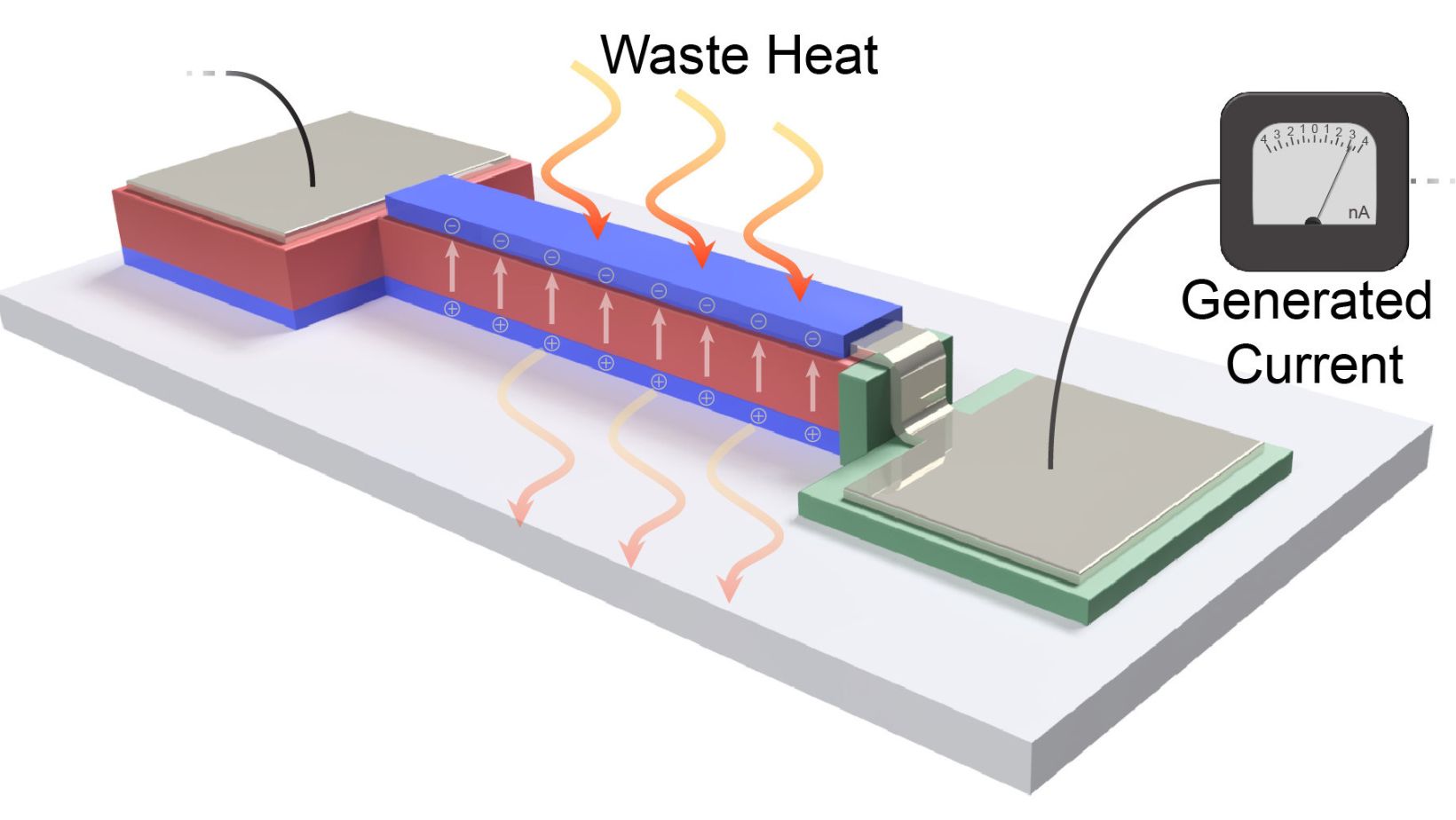

Harnessing the sun’s power to generate electricity is made possible through thin-film photovoltaic cells. These solar panels are lightweight, flexible, and cost-effective, making them popular for various applications, from residential rooftops to portable solar chargers.

Touchscreen Displays

Smartphones, tablets, and current touchscreens rely on capacitive touch technology, which detects the contact of a finger or stylus using transparent, conductive thin sheets. These thin films allow for precise and responsive touch interactions, revolutionizing how we interact with electronic devices.

Hard Disk Drives

Thin film technology is essential in the data storage business. Magnetic thin films are used in hard disk drives to store and retrieve digital information. Advances in thin film materials have increased storage capacity and faster data access speeds in these essential devices.

Flexible Electronics

Thin film technology enables the creation of flexible and bendable electronic devices, such as e-paper displays, wearable sensors, and even roll-up keyboards. These innovations open up new possibilities for compact and portable electronic gadgets.

Anti-Corrosion Coatings

Thin film coatings can protect many materials from corrosion, increasing lifespan and lowering maintenance costs. Applications include protective coatings on aircraft, bridges, and pipelines and corrosion-resistant layers on everyday objects like kitchen utensils.

Optical Filters

Thin film interference technology is utilized in optical filters used in cameras, microscopes, and other imaging instruments to selectively transmit or block specific wavelengths of light. This improves image quality and color accuracy in photography and scientific research.

What Role Does Thin Film Technology Play In The Healthcare Industry?

Some of the critical roles of thin film technology in healthcare include:

Biosensors

Thin films are essential in biosensors to detect biological molecules, pathogens, and biomarkers. These sensors are critical for medical diagnostics since they allow for the rapid and sensitive identification of diseases and conditions like diabetes, cancer, and infectious infections.

Drug Delivery Systems

Thin film technology creates drug delivery systems that can release medications at controlled rates. Thin film drug patches, implants, and micro-needles provide precise dosing. They can improve patient compliance by eliminating the need for frequent dosing.

Implantable Devices

Thin film coatings can be applied to medical implants to enhance their biocompatibility and functionality.

For example, thin films can modify the surface properties of orthopedic implants, dental implants, and cardiovascular stents to improve tissue integration and reduce the risk of complications.

Diagnostic Devices

Thin film-based diagnostic devices, such as lab-on-a-chip and microfluidic devices, enable rapid and cost-effective testing for various medical conditions. These devices can analyze blood samples, detect pathogens, and perform genetic testing in a miniaturized format.

Wearable Health Monitoring

Flexible and thin film-based sensors can be integrated into wearable devices to monitor vital signs, such as heart rate, temperature, and blood pressure. These sensors provide real-time data to healthcare professionals and patients, aiding in remote monitoring and early disease detection.

Conclusion

Thin film technology is a hidden but integral part of our everyday lives, impacting various industries and enhancing our experiences unexpectedly. From improving our vision with anti-reflective coatings to powering our electronic devices with thin film solar panels, the applications of this technology are vast and continually evolving. As we continue to explore and develop thin film materials and techniques, we can expect even more surprising uses to emerge, further enriching our daily experiences.