In a world where everything seems to be made of plastic or cardboard, titanium 3D printing swoops in like a superhero, ready to save the day! This cutting-edge technology offers a way to create strong, lightweight parts that can withstand the harshest conditions. Forget about flimsy materials that bend at the first sign of pressure; titanium is here to flex its muscles and prove it’s the heavyweight champion of the 3D printing ring.

Table of Contents

ToggleTitanium 3D Printing

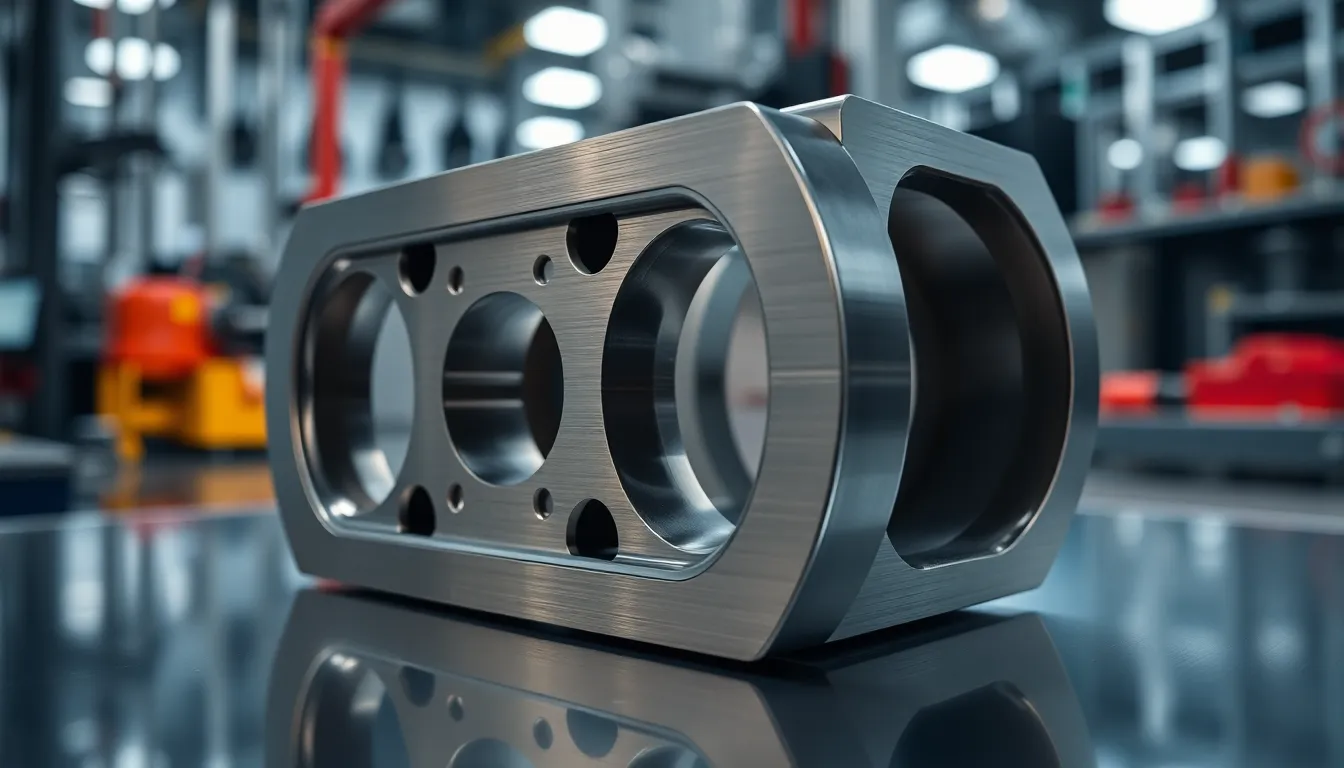

Titanium 3D printing utilizes additive manufacturing techniques to create complex, lightweight structures with exceptional mechanical properties. Known for its high strength-to-weight ratio, titanium is also resistant to corrosion, making it suitable for various applications, including aerospace, medical implants, and automotive components.

Additive manufacturing processes, such as Electron Beam Melting (EBM) and Selective Laser Melting (SLM), facilitate the production of titanium parts by melting powder layers. SLM employs lasers to fuse titanium powder, while EBM uses electron beams in a vacuum environment. Both methods ensure accurate layer bonding, enabling the production of intricate geometries unattainable through traditional manufacturing.

Cost considerations arise when implementing titanium 3D printing. Although it may offer reduced material waste and shorter lead times, initial costs for titanium powders and equipment can be high. High-quality titanium alloy powders, for example, often come at a premium price. Despite these costs, industries frequently find that the benefits, such as lightweight designs and enhanced performance, outweigh initial investments.

Applications demonstrate the versatility of titanium 3D printing across multiple sectors. Aerospace companies, for instance, use this technology to produce components like brackets and engine parts that meet strict weight requirements. Medical industries also embrace it for custom implants tailored to individual patients, ensuring better fit and performance.

Strength and durability define products made with titanium 3D printing. These characteristics allow for reliable usage in demanding environments. As a result, titanium continues to emerge as a favored material in the burgeoning field of 3D printing, offering significant advantages over conventional materials for specialized applications.

Benefits of Titanium 3D Printing

Titanium 3D printing offers multiple advantages, making it a leading choice in various industries. Key benefits include its lightweight yet strong nature along with impressive corrosion resistance.

Lightweight and Strong

Titanium boasts a high strength-to-weight ratio, standing out in demanding applications. Aerospace companies leverage this characteristic to reduce overall weight while maximizing structural integrity. Engineers design custom components, utilizing titanium’s ability to withstand heavy loads without compromising performance. Additionally, products made from titanium outperform those crafted from conventional materials in strength tests. Lightweight structures contribute to fuel efficiency in transportation sectors, enhancing both performance and sustainability over time.

Corrosion Resistance

Titanium showcases remarkable resistance to corrosion, making it ideal for harsh environments. Its ability to naturally form a protective oxide layer prevents degradation even in extreme conditions. Industries such as marine and chemical rely on titanium for components exposed to saltwater or acidic substances. Medical applications also benefit from this property, as titanium implants remain biocompatible and stable within the human body. Longevity results from titanium’s durability, minimizing the need for replacements and repairs, thus lowering overall maintenance costs.

Applications of Titanium 3D Printing

Titanium 3D printing excels in various industries, showcasing its unique advantages in producing lightweight, strong parts.

Aerospace Industry

Aerospace companies continually rely on titanium 3D printing for crafting lightweight components that enhance fuel efficiency. Structures made from titanium can withstand extreme conditions, making them suitable for aircraft and spacecraft. Weight reduction directly correlates with improved performance, allowing manufacturers to maximize operational efficiency. Production of complex geometries through additive manufacturing leads to fewer parts, simplifying assembly. Parts created via Electron Beam Melting (EBM) or Selective Laser Melting (SLM) provide significant strength, ensuring safety and durability in flight.

Medical Devices

In the medical field, titanium 3D printing revolutionizes the creation of custom implants. Tailored solutions ensure a precise fit for patients, promoting improved recovery outcomes. Biocompatibility remains a crucial factor, as titanium minimizes the risk of rejection by the body. Manufacturers leverage additive technologies to design intricate structures that mimic natural bone, facilitating better integration. Medical devices produced using titanium offer longevity and resistance to corrosion, enhancing their usefulness in surgical applications.

Automotive Sector

The automotive sector embraces titanium 3D printing for producing lightweight components that contribute to overall vehicle performance. Engineers design parts that can withstand thermal and mechanical stress, providing durability without adding excessive weight. Speed in prototyping allows for rapid innovation, resulting in quicker time-to-market for new models. Integration of titanium engine components can lead to improved fuel efficiency while maintaining structural integrity. The ability to create complex parts using additive manufacturing enhances design flexibility, meeting the increasing demands of modern vehicles.

Challenges in Titanium 3D Printing

Titanium 3D printing poses several challenges that can impact its widespread adoption. Understanding these obstacles is essential for maximizing its potential.

Material Costs

High material costs represent a significant barrier in titanium 3D printing. Titanium powders, essential for additive manufacturing, often cost between $50 and $200 per kilogram. Prices vary based on purity and particle size. Industries may hesitate to invest due to these expenses. Nevertheless, the reduction in waste materials through efficient additive processes can offset some costs over time. Organizations must consider long-term savings while evaluating initial investments in titanium.

Technical Limitations

Many technical limitations affect the capabilities of titanium 3D printing. Notably, certain designs may become challenging to produce due to the intricate nature of titanium parts. Process parameters, such as laser power and scanning speed, must be carefully calibrated to achieve optimal results. Equipment may also require frequent maintenance, leading to downtime that impacts production timelines. Furthermore, post-processing techniques can add complexity and time to the workflow. Addressing these technical challenges is crucial for enhancing the efficiency and effectiveness of titanium 3D printing.

Future of Titanium 3D Printing

Advancements in titanium 3D printing technology promise to reshape multiple industries. Researchers continuously explore methods to reduce production costs, aiming to make titanium accessible for even small-scale operations. Increased investments in research and development foster innovation in producing titanium powders, enhancing their affordability and availability. This shift opens doors for diverse applications beyond traditional sectors.

Industry experts recognize the potential of titanium alloys to expand the capabilities of 3D printing. Combining titanium with other metals could yield materials with tailored properties, optimizing performance for specific applications. Enhanced properties could include improved strength, better fatigue resistance, and lighter weights, making them ideal for aerospace and automotive components.

Demand for lightweight, durable materials drives the growth of titanium 3D printing in new areas. The medical field stands to benefit significantly through custom implants and prosthetics designed for individual patients. Tailored approaches in the medical sector promote better integration and recovery outcomes for patients, resulting in continued trust in titanium’s benefits.

The sustainability of titanium 3D printing emerges as a critical concern. By minimizing waste during production, this technology supports environmentally conscious practices. As regulations on material sourcing and waste management tighten, titanium’s recyclability makes it an attractive option for manufacturers aiming to enhance their green credentials.

Interest in integrating artificial intelligence and machine learning alongside titanium 3D printing processes continues to grow. AI-driven optimization techniques can streamline workflows, improve design efficiencies, and enhance quality control. Companies embracing these technologies can expect to improve their competitive edge as they adapt to evolving market demands.

Conclusion

Titanium 3D printing stands at the forefront of manufacturing innovation. Its unique properties make it an ideal choice for industries seeking lightweight yet robust materials. As technology progresses and costs decrease, titanium’s adoption will likely expand.

The potential for customized solutions in sectors like aerospace and healthcare highlights its versatility. With ongoing advancements in production techniques and materials, titanium 3D printing is set to redefine standards across various applications.

Embracing this technology not only enhances performance but also supports sustainable practices by reducing waste. The future looks promising as industries leverage titanium’s advantages to push the boundaries of what’s possible in 3D printing.