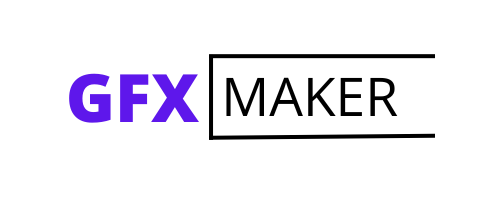

As 3D printing becomes more popular, more people are starting to design 3D printable models. If you’re new to the process, it can be difficult to know where to start. In this article, we’ll walk you through the basics of designing 3D print models. We’ll cover topics such as software options, file types, and scaling your designs. By the end of this tutorial, you’ll be ready to start creating your own 3D printable models! You’re going to have a lot of fun with this guide, and I’m going to be showing you how to design 3D print models for your own personal use or for sale!

Modeling a 3D print is an important part of the 3D printing process. Modeling to be used on a 3D printer requires more than just basic design knowledge. The 3D model must also be very well designed in relation to the limitations and possibilities of how a certain object will be printed. The presented article covers the basic design rules for creating a 3D print model and provides links to further properties that can be utilized in the different stages of 3D printing.

Table of Contents

ToggleChoose the right size model.

When designing a 3D print model, it’s important to choose the right size.

When you’re designing a 3D print model, it’s important to choose the right size. If your model is too big or too small, it can have a negative impact on your end result.

Too big? Your model will take longer to print, and you may run out of material before the print is finished.

Too small? Your model might not get enough support from the printer’s software, which means that parts of your design could be missing when you remove them from the machine.

https://3dsolved.com/create-models-for-3d-printing/

Break up your model into multiple parts.

When it comes to designing 3D print models, you’ll have to break the model down into multiple parts. This is because each part will be printed separately and then assembled. If you don’t do this, the printer will not be able to tell where one part ends and another begins, and it won’t be able to print correctly.

To make sure your model prints correctly, follow these steps:

1) Start with a simple shape that forms the base of your object. It should be as basic as possible—the simplest shape possible (like a cube or a cylinder).

2) Add other shapes on top of this base shape that makes up even smaller parts of your model. These new shapes should also be very simple and easy to understand so that they print properly on their own without requiring any further instructions from you about how they should look or behave when they’re finished printing!

Design your parts around the build plate.

When designing 3D print models, it is important to consider the build plate. The build plate is the surface on which your model is printed. When you are designing a part for 3D printing, you will need to account for the size of your printer’s build plate.

In some cases, the size of a printer’s build plate may be smaller than what you would like to print. This is especially true if you have a large part that needs to be printed in one piece. In this case, there are several options available to you:

You can split your model into multiple parts and print each part separately (or use supports). This option requires more time and effort but may still result in an accurate product with minimal waste material from supports. You can use support structures or rafts to help keep delicate parts from warping during printing. This approach also requires more time and effort but can produce accurate results with less wasted material.

You can print your model larger than its final size, then resize it later by cutting off excess material from the edges of each printed layer using a Dremel tool or similar rotary tool (such as an X-Acto knife). This approach requires less time than other methods.

Make ribs stronger than they need to be.

Ribs are an essential part of any house, bridge, or building. They provide support, and their shape allows the structure to expand and contract with changes in temperature. However, ribs can also cause problems if they are too strong.

https://all3dp.com/1/best-free-3d-printing-software-3d-printer-program/

We’ve developed a new technology that allows us to print ribs that are only as thick as they need to be for structural integrity while still having all of the benefits of thicker ribbing such as insulation and stability during extreme weather conditions like hurricanes or tornadoes (which can cause significant damage even when they don’t directly hit your home).

Design flat surfaces that are parallel to the build plate.

When designing 3D print models, it’s important to keep in mind that the surface of the model must be flat. If it isn’t, the printer won’t be able to print properly.

The easiest way to do this is by using Tinkercad’s built-in tools for checking your model’s flatness. Open up your model in Tinkercad and click on “Check Flatness” in the top menu bar (it looks like a square with an arrow pointing down).

This will activate an algorithm that analyzes your model’s shape and determines whether or not it is flat enough for printing. It will give you an estimate of how much material would need to be removed to make it completely flat. If needed, you can use these estimates as a guide when manually editing your models before printing them out.

Use minimal height for supports.

When designing for 3D printing, you can use a minimum height for supports. This is because the supports are not required to be removed from the model after it is printed.

In order to minimize the amount of material used in your print, you should use minimal support structures. Minimal support structures are typically about 0.4mm high and are printed on top of your model. They will hold up your model as it is being printed, but they do not need to be removed after printing because they do not affect the final product.

The process of adding supports is called “Generating Support Material,” and it’s done by selecting “Add Support” in your printer software or clicking on “Support Material” when editing a model’s settings in Tinkercad.

https://ultimaker.com/learn/what-software-to-use-for-3d-printing

To design and print 3D models it is important to be mindful of different factors including how they will fit on the build plate and how tall they can be before it has to use supports.