Imagine cruising down the highway in a car that’s not just a mode of transport but a masterpiece of modern technology. 3D printing car parts is revolutionizing the automotive industry, turning the impossible into reality. Gone are the days of waiting weeks for a replacement part or paying an arm and a leg at the dealership. Now, it’s all about instant gratification and creativity, and who doesn’t love a good DIY project?

With the rise of 3D printing, car enthusiasts and manufacturers alike are discovering the thrill of customizing their rides like never before. Whether it’s a sleek new dashboard or a quirky cup holder shaped like a dinosaur, the possibilities are endless. Get ready to buckle up and explore how this innovative technology is reshaping the way we think about car parts—because let’s face it, who wouldn’t want a car that’s as unique as they are?

Table of Contents

Toggle3D Printing Car Parts

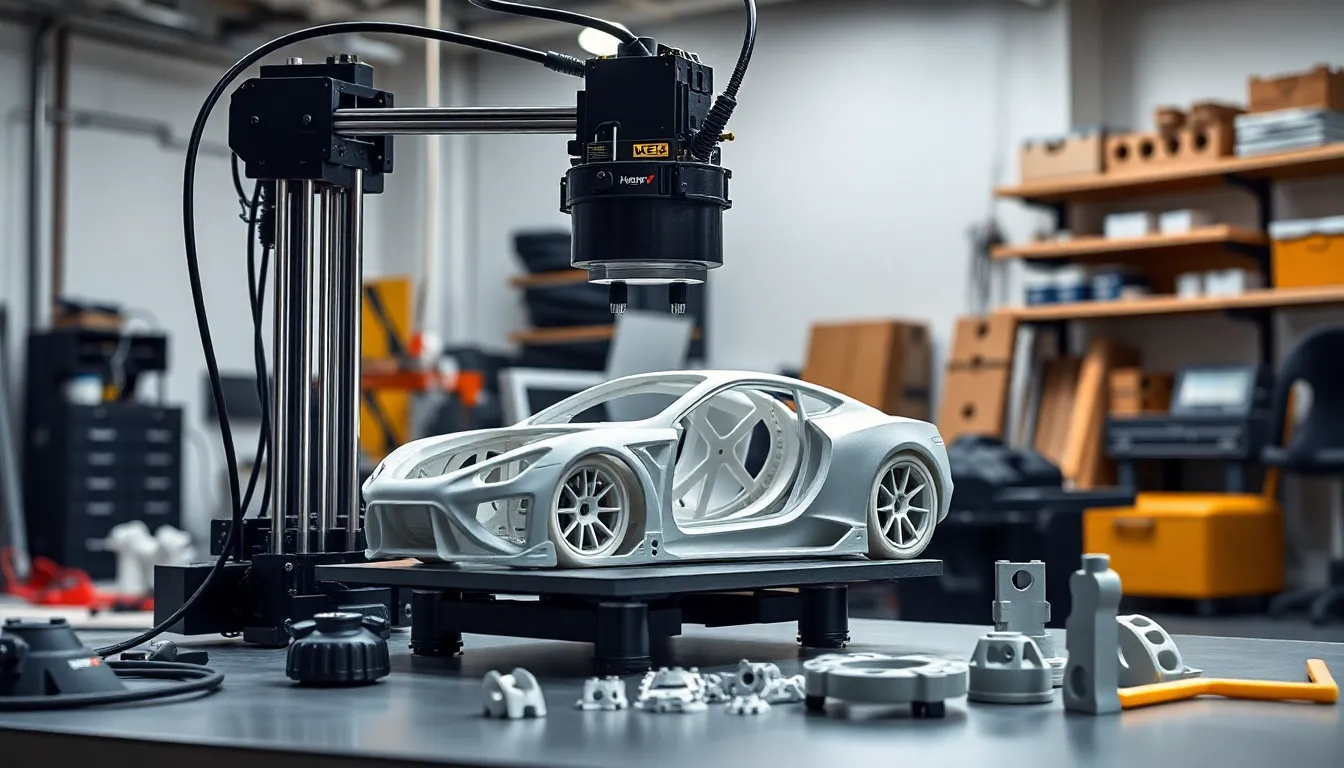

3D printing revolutionizes the production of car parts by enabling rapid and cost-effective manufacturing processes. Both manufacturers and enthusiasts benefit from the ability to create customized components, enhancing vehicle aesthetics and functionality. The technology allows for the creation of intricate designs and lightweight materials, which traditional manufacturing methods often cannot achieve.

Automakers utilize 3D printing for prototyping new car parts, enabling design adjustments at minimal cost. Speed plays a critical role in the process, as companies can produce parts within hours rather than weeks. Customization options expand significantly with 3D printing, allowing for production of unique features, such as personalized dashboards and specialty accessories.

Material diversity is another advantage of 3D printing in the automotive sector. Thermoplastics, metals, and composites can be utilized to manufacture durable components. Specific materials provide strength while maintaining lightweight properties, improving overall vehicle performance. For instance, carbon fiber reinforced plastics increase resilience and offer enhanced design flexibility.

Additionally, 3D printing supports sustainable manufacturing practices. Reducing waste during production aligns with the industry’s growing focus on eco-friendliness. Components can be produced on-demand, minimizing inventory needs and lowering storage costs.

The future of 3D printing in automotive production promises ongoing innovation. As technology advances, possibilities for on-site manufacturing and repairs increase. Enhanced accessibility and affordability of 3D printers may further stimulate growth in the automotive aftermarket. Overall, the integration of 3D printing signifies a new era for car part manufacturing, reshaping how vehicles are designed and produced.

Benefits Of 3D Printing Car Parts

3D printing car parts offers significant advantages. These benefits enhance both production efficiency and vehicle customization options.

Cost Efficiency

Cost efficiency stands out as a primary advantage. Traditional manufacturing methods often involve high tooling costs and lengthy production timelines. With 3D printing, manufacturers cut expenses associated with molds and reduce waste, as materials are used precisely where needed. Companies can produce parts on-demand, minimizing inventory storage costs. Estimates show that companies can save up to 70% on production costs when utilizing 3D printing for prototyping and low-volume production. Savings add up quickly as businesses streamline operations while increasing output.

Design Flexibility

Design flexibility characterizes 3D printing technology. It allows for intricate shapes and complex geometries that conventional methods cannot produce. Designers innovate without restrictions, experimenting with unique features and lightweight structures to enhance performance. 3D printing enables rapid prototyping, allowing for swift iterations based on testing and feedback. Customization options empower enthusiasts to create personalized components that reflect their style, from customized grilles to bespoke rear spoilers. This flexibility fosters creativity in car design and production, broadening the scope of possibilities in the automotive industry.

Applications In The Automotive Industry

3D printing significantly enhances various applications within the automotive sector. Not only does it streamline processes, but it also opens up innovative possibilities in design and production.

Prototyping

Prototyping leverages 3D printing’s rapid capabilities. Designers utilize this technology to quickly create and test new parts. Iterations occur faster, allowing for design modifications with minimal expenditures. Manufacturers can assess fit and functionality without committing extensive resources to traditional manufacturing methods. This quick turnaround cultivates an environment for creativity and experimentation. Ultimately, prototypes can evolve into final products more efficiently, reducing time-to-market.

Production Parts

Production parts benefit from 3D printing’s unique attributes. Manufacturers create intricate components that would otherwise be challenging or costly to make using traditional methods. Customization becomes easier, tailoring parts to specific vehicle models or customer preferences. The reduction in tooling and machining time leads to significant cost savings. Furthermore, components produced through 3D printing showcase enhanced performance due to optimized designs. On-demand production reduces the need for large inventory, effectively lowering overhead costs. This shift revolutionizes how the automotive industry approaches both standard and bespoke parts manufacturing.

Challenges In 3D Printing Car Parts

3D printing car parts presents several challenges that impact the effectiveness and scalability of this technology in the automotive industry.

Material Limitations

Material limitations significantly affect the feasibility of 3D printing car parts. Not all materials used in traditional manufacturing are suitable for 3D printing processes. While thermoplastics and certain metals are widely utilized, they often lack the necessary strength or durability for critical automotive applications. Additionally, specific printing technologies may have compatibility issues with some materials. Material strength can vary based on the printing method, which complicates the determination of performance characteristics in real-world scenarios. The industry continually explores new materials to expand usable options, making ongoing research vital for advancing 3D printing applications.

Regulatory Issues

Regulatory issues pose significant hurdles for 3D printing car parts. Automotive manufacturers must comply with stringent safety standards and certifications set by governing bodies. Meeting these rigorous requirements involves extensive testing and validation. Such processes can be time-consuming and costly, hindering rapid market entry for new parts. Furthermore, the legal framework surrounding the use of 3D printed components remains underdeveloped, creating uncertainty regarding liability and intellectual property rights. As the technology evolves, collaboration among industry stakeholders and regulators is necessary to establish clear guidelines that ensure safety and promote innovation in 3D printing for automotive applications.

Future Trends In 3D Printing Car Parts

Advancements in 3D printing technology continue to shape the future of car parts manufacturing. Increased automation processes enhance efficiency, allowing manufacturers to streamline production and reduce labor costs. Intelligent software and machine learning also play crucial roles, optimizing designs and predicting material performance to improve sustainability in automotive applications.

Customization emerges as a key focus for many manufacturers. Personalization grows more significant, with consumers seeking unique designs for their vehicles. The ability to create bespoke car parts on demand encourages creativity and fosters a deeper connection between car owners and their vehicles.

Integration of advanced materials marks another notable trend. Companies increasingly experiment with composites, metal alloys, and bio-based plastics to improve strength and reduce weight. These innovations expand the scope of what is achievable in car part design, unlocking new possibilities for performance and safety.

Collaborative development efforts enhance the industry’s progress in 3D printing. Industry stakeholders, including automotive manufacturers, material suppliers, and technology firms, actively collaborate to address challenges. This synergy promotes knowledge sharing and drives innovation, resulting in improved processes and products.

Regulatory frameworks also evolve to meet the growing presence of 3D printing in the automotive sector. Policymakers adapt safety standards and guidelines to accommodate novel manufacturing techniques. Manufacturers gaining insight into compliance measures can facilitate faster market entry for new car parts, benefiting consumers and boosting competition.

Sustainability initiatives gain traction within the industry. Companies adopt eco-friendly practices, reducing waste and emissions during production. Emphasis on recycling and circular economy principles drives further advancements in designing for reuse, enhancing the industry’s environmental impact.

Embracing these trends positions the automotive sector for a transformative future, as 3D printing continues to redefine production methodologies and elevate design possibilities.

Conclusion

The future of the automotive industry is undeniably intertwined with 3D printing technology. As manufacturers and enthusiasts embrace its potential for customization and rapid prototyping, they’re opening doors to unprecedented design possibilities. The ability to create intricate parts while minimizing costs and waste is revolutionizing production methods.

While challenges like material limitations and regulatory hurdles remain, ongoing research and collaboration are paving the way for innovative solutions. With advancements in automation and sustainable practices on the horizon, 3D printing is set to redefine how vehicles are designed and produced. The automotive sector stands on the brink of a transformative era, fueled by creativity and technological progress.