Imagine a world where your wildest ideas leap off the drawing board and into your hands—welcome to the realm of Odyssey 3D printing. This isn’t just about creating objects; it’s about transforming dreams into reality, one layer at a time. Whether it’s a quirky coffee mug shaped like a cat or a prototype for the next big tech gadget, Odyssey 3D printing makes it happen with precision and flair.

Table of Contents

ToggleOdyssey 3D Printing

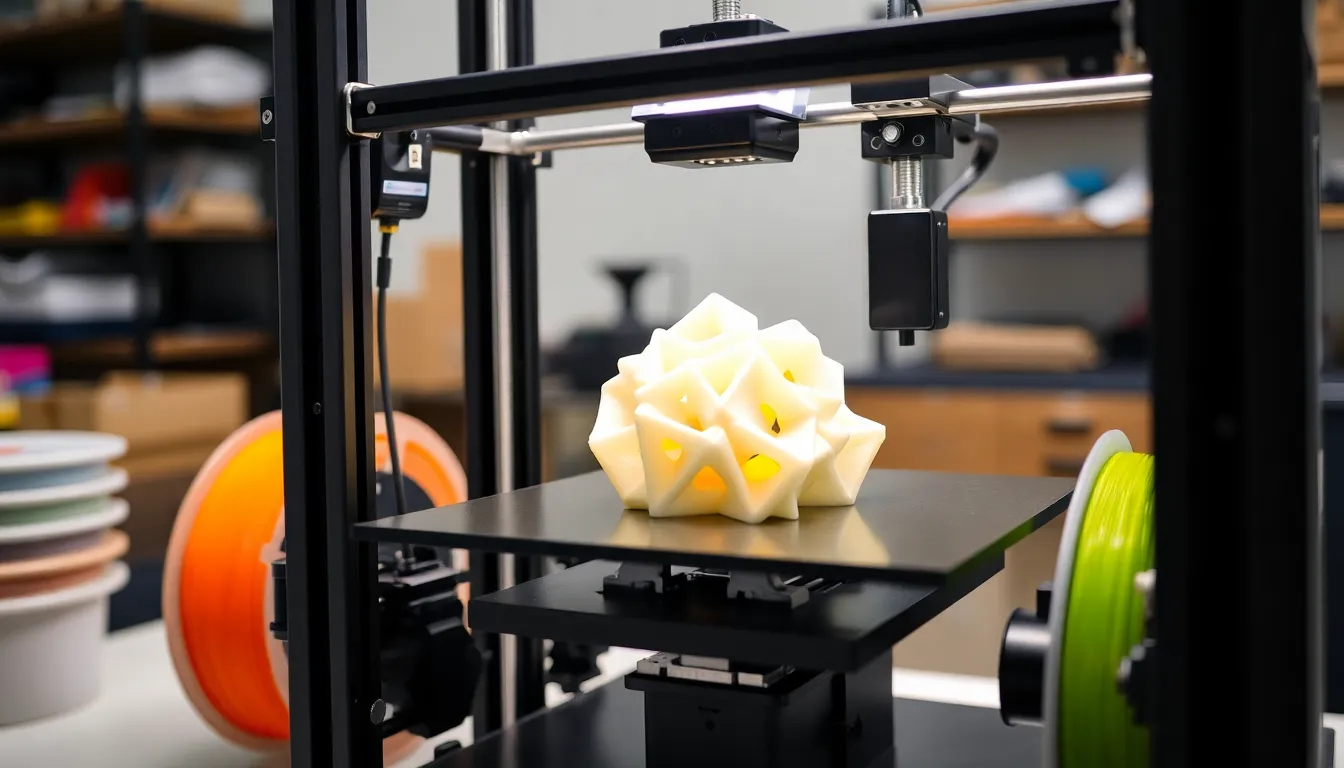

Odyssey 3D printing encompasses advanced techniques, enabling rapid prototyping and production of complex geometries. This technology utilizes various materials, including plastics, metals, and ceramics, tailoring outputs for specific applications. Enhanced precision characterizes the process, ensuring high-quality results for intricate designs.

Users benefit from a range of printing methods, such as fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Each method serves unique purposes, addressing diverse requirements in industries like aerospace, automotive, and healthcare. Through these methods, professionals can create functional parts or aesthetic models with impressive efficiency.

Speed stands out as a key advantage of Odyssey 3D printing, allowing for rapid iterations and faster market entry. Design modifications can occur swiftly, accommodating the dynamic nature of product development. Cost-effectiveness also plays a crucial role, as it reduces waste and lowers manufacturing costs, particularly in low-volume production runs.

Sustainability presents an additional benefit. Many 3D printing processes minimize material waste, supporting eco-friendly practices. Users increasingly appreciate these environmental advantages, as they align with global sustainability goals.

With continued advancements in technology, the future of Odyssey 3D printing promises further enhancements. Improved material options and more efficient machines aim to refine quality and expand capabilities. This evolution positions Odyssey 3D printing as a critical asset across various sectors, driving innovation and creativity in design and manufacturing.

Benefits of Odyssey 3D Printing

Odyssey 3D printing offers numerous advantages, making it a preferred choice in various industries. These benefits include enhanced design flexibility and cost efficiency.

Enhanced Design Flexibility

Enhanced design flexibility stands as a core benefit of Odyssey 3D printing. Users can create intricate designs that traditional manufacturing methods often struggle to achieve. Customization becomes straightforward, allowing for unique products tailored to specific needs. The ability to rapidly prototype makes it easier to iterate designs based on feedback. Different materials can be used to achieve various finishes and functional properties, expanding creative possibilities. This technology supports complex geometries that enhance both aesthetics and performance, enabling innovation across sectors such as automotive and aerospace.

Cost Efficiency

Cost efficiency serves as another significant advantage of Odyssey 3D printing. Traditional methods often involve high tooling costs and extended lead times. In contrast, 3D printing minimizes material waste by using only the necessary amount of material. Lower production costs emerge from the ability to produce small batches without additional setup expenses. Time savings in production and design cycles can significantly reduce overall project costs. Additionally, this technology allows for on-demand manufacturing, further cutting down inventory costs and risks associated with excess stock. This combination of factors positions Odyssey 3D printing as a financially viable option for companies looking to innovate.

Applications of Odyssey 3D Printing

Odyssey 3D printing showcases a range of applications across various industries. Its versatility allows users to leverage technology effectively.

Prototyping and Product Development

Prototyping stands as a primary application of Odyssey 3D printing. Designers quickly turn concepts into physical models, enhancing the product development cycle. Rapid iterations are possible, enabling improvements based on immediate feedback. Different materials can simulate real-world properties, ensuring realistic evaluations of prototypes. Industries like automotive and aerospace benefit significantly, as reduced lead times expedite their paths to market. Complex geometries also become easily achievable, allowing for innovative designs that traditional manufacturing might struggle to produce.

Educational Uses

Educational institutions widely utilize Odyssey 3D printing for hands-on learning. Students engage in creative projects, bringing theoretical concepts to life through physical models. It aids in teaching complex subjects like engineering, physics, and art. Various projects promote collaboration and problem-solving skills among learners. Additionally, the technology encourages innovation, allowing students to experiment and iterate on their designs. Classes can dive into the engineering process, emphasizing design thinking and functionality. This interactive approach cultivates a deeper understanding of material properties and design principles.

Technologies Behind Odyssey 3D Printing

Odyssey 3D printing operates through a combination of cutting-edge software and innovative materials, driving its effectiveness in various industries.

Software Innovations

Software solutions play a crucial role in Odyssey 3D printing. Advanced slicing software prepares 3D models for printing, optimizing layer height and infill patterns. Cloud-based applications enable remote monitoring and control of print jobs, enhancing accessibility. Integration with computer-aided design (CAD) programs streamlines the transition from digital designs to physical objects. Additionally, simulation software predicts potential print errors, increasing reliability. These innovations significantly enhance workflow efficiency, allowing designers to focus on creativity rather than technical challenges.

Material Advancements

Material advancements fuel the growth of Odyssey 3D printing technology. Innovations in thermoplastics, such as ABS and PLA, offer enhanced strength and flexibility. These materials cater to diverse applications, from prototyping to final products. Recently developed composites incorporate metals and ceramics, providing improved durability for functional parts. Bio-based and recycled materials align with sustainability goals, minimizing environmental impact. Developing new materials expands the creative possibilities for designers, empowering them to tackle increasingly complex projects with confidence.

Challenges in Odyssey 3D Printing

Odyssey 3D printing encounters various challenges that can impact its effectiveness across different industries. High material costs present a significant obstacle, as specialized filaments and resins often require a larger upfront investment, which affects overall production budgets. Limited access to advanced machines can also hinder performance, especially for small businesses that cannot afford high-end printers.

Printer calibration remains a critical concern. Inaccurate settings can lead to print failures or inconsistent results, necessitating time-consuming adjustments to maintain quality standards. Furthermore, complex geometries often complicate the printing process. While they provide design flexibility, they increase the likelihood of structural weaknesses and require careful consideration during the design phase.

Post-processing steps introduce additional complexities. Many printed items need sanding, polishing, or painting to achieve the desired finish, extending project timelines and adding costs. Temperature and humidity fluctuations can also impact print quality, especially with sensitive materials, demanding more rigorous environmental controls.

Moreover, regulatory compliance emerges as a challenge in specific industries. Adhering to safety and material standards is essential, especially in sectors like healthcare and aerospace, where product safety is paramount. When using new materials or techniques, obtaining necessary certifications can be a lengthy procedure.

Intellectual property concerns are prevalent as well. Due to the ease of replicating designs, protecting proprietary intellectual creations becomes increasingly complex in the world of 3D printing. This complicates the commercialization of innovations and raises questions about ownership and rights.

Developers, therefore, must navigate these challenges while leveraging the advantages that Odyssey 3D printing offers. Continuous advancements and industry collaboration aim to address these hurdles, fostering a more efficient and sustainable future for this transformative technology.

Conclusion

Odyssey 3D printing stands at the forefront of innovation, reshaping how industries approach design and production. Its ability to transform ideas into reality with unmatched precision and speed is revolutionizing sectors from aerospace to healthcare. As technology continues to evolve, the potential for creativity and efficiency expands, paving the way for groundbreaking applications.

While challenges remain, the benefits of Odyssey 3D printing far outweigh the obstacles. By fostering collaboration and embracing advancements in materials and software, the industry can overcome hurdles and unlock new possibilities. This technology not only enhances product development but also encourages sustainable practices, ensuring a brighter future for manufacturing.